The History of Fiberglass Tank Solutions

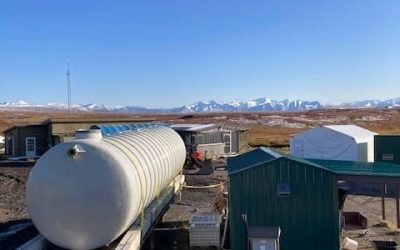

Our base of operations for Fiberglass Tank Solutions LLC is centrally located in Missouri near Lake of the Ozarks. Using this Midwest location allows us to service the entire North American marketplace from one central point of manufacturing in the US.

Our Fiber Reinforced Plastic (FRP) tank production and assembly is done onsite within a 78,000-square-foot Under-roof facilities and other fabrication shops on one 14.5 Acre Manufacturing Campus, which provides the needed horizontal and vertical workspace to safely and efficiently fabricate and assemble these large-diameter tank packages for underground storage tanks.

You can be guaranteed that our packaged systems will be built to your specifications with quality, realistic delivery dates, at a competitive price.

Core Values

Honesty | Longevity | Accountability | Loyalty | Family-Oriented

Mission Statement

FTS is a family-owned & operated enterprise, we provide our precious time, sweat equity, and personal investment in our business to build and empower success for our customers, employees, and vendors. Our focus and actions will always be targeted to generate a business transaction that is honest, profitability, and successful for all parties.

Vision Statement

We build the strongest engineered backed tanks with the most competitive price in the market by maintaining low overhead, creating strong & competitive supply-side relationships for family-owned businesses, while also using personal ingenuity skills in our manufacturing process.

Our Team

Kevin Hawthorne

Owner / Management Member

University of Missouri 1985: B.S Agriculture Economics

Kevin Hawthorne founded Fiberglass Tank Solutions, LLC in 2012 with the goal of creating a one-of-a-kind manufacturer of Fiberglass Reinforced Plastics (FRP) that uses large diameter molding to build fully customized pre-kitted lift stations and rehabilitation inserts for the municipal and industrial wastewater lift station collection markets.

Kevin has spent the last 12 years developing this fiberglass manufacturing firm with unique and innovative skills in building modern solutions for turnkey large-diameter Underground Storage Tanks (UST), Wet Wells, and fiberglass inserts for the rehabilitation of concrete wet wells.

Matt Callanan

Project Manager | Technical Inside Sales

University of Central Missouri- 2009: Science in Computer-Aided Drafting and Design Technology.

Matt played a key role in getting FTS off the ground by designing customized Wet Wells and USTs. Under the guidance of Kevin, Matt expanded his role to include technical sales, project management, and estimating, contributing to the company’s success.

Outside of work, Matt enjoys remodeling and home improvement projects, as well as camping, fishing, and golfing. He loves spending time with his wife Katy and their two children, exploring the Lake of the Ozarks and savoring its excellent meals and activities during the summer. Together, they take their boat out to one of the many coves and appreciate the tranquility of the slower winter months. Matt’s diverse skills and enthusiasm make him an appreciated member of the FTS team.

Kyle Cribb

Owner / Operations Manager

Kyle is our Production Supervisor at FTS and an ACMA Certified Composites Technician. He leads our Quality Control program, ensuring all projects meet exact specifications before leaving our shop.

Kyle brings extensive experience from construction projects worldwide and strives for perfection in every aspect of his work. His dedication to quality and attention to detail plays a critical role in our daily operations.

Outside of work, Kyle, his wife Candice, and their two children engage in a diverse range of interests and activities. They continually seek synergy with the world around them, exploring and enjoying life together. Kyle’s commitment to excellence and passion for his work make him a treasured asset to the FTS team.

Sara Hamm

Project Coordinator

Northwest Missouri State University – Bachelor of Science in Business Management

Sara joined the Fiberglass Tank Solutions family in July 2019. Since then, she has expanded her responsibilities to include purchasing orders, logistics, project coordination, communication across departments, and accounting duties. Her customer service experience and logistics expertise contribute to our company’s smooth operations. Life may be a roller coaster, but once you speak with Sara about your project requirements, you’ll be looking for that souvenir photo to remember the wonderful experience.

Sara, her husband Brad, and their daughter enjoy anything adventurous, horseback riding, kayaking, hiking, biking, camping, spending time with family and friends, gardening, and caring for all of their animals. The farm keeps her family busy, but everyone enjoys the sweet treats she brings into the office.

Jack Crow

Project Manager | Technical Inside Sales

Jack Crow is a skilled professional at FTS, where he joined the team in the fall of 2019. He attended Kansas State University, studying Construction Science and Management, before making his home in Sunrise Beach, Missouri. At FTS, Jack creates submittal drawings for, turnkey USTs, custom prefabricated lift stations, and valve vaults. Expanded his responsibilities to include project estimates, ordering take-offs, production drawings, and buoyancy calculations. He is also actively involved in innovating new products, tools, and methods to support FTS’s growth.

In his spare time, Jack enjoys the Lake of the Ozarks’ fishing opportunities and its serene surroundings. He spends time with friends, contributes to local charities, and appreciates the lake’s nightlife. Additionally, he finds relaxation kayaking on the tranquil waters. Jack’s multifaceted interests and dedication make him a valued member of the FTS team.

Andres Aguilera

Shop Foreman

Andres has over 25 years of experience making fiberglass tanks. He began his career as an entry-level manufacturer of FRP industrial tanks and has spent the last decade honing his lamination trade skills via hard labor. With hands-on experience, obtaining substantial and valuable layperson skills and knowledge in the unique fiberglass tank manufacturing business. Andres has developed and manufactured unique tanks for a variety of applications and industries during his career. Andres became a part of FTS’s manufacturing solutions in 2016 and has grown with the company to his current position as Shop Foreman for both our Fabrication and Assembly divisions.

Andres enjoys spending his leisure time working on his small acreage farm, where he yields a unique breeding stock of game roosters. He enjoys spending time with his son, mother, brother, and close extended family. Andres enjoys making his favorite traditional authentic Mexican dishes for his family and friends at regular family gatherings.

Anton Funtek

SolidWorks Drafter

Anton Funtek brings extensive expertise in Drafting and Design to FTS. He utilizes SolidWorks to turn our customers’ visions into reality, employing 3D drawings and 2D concept views to ensure precise and efficient designs. Anton’s contributions extend to developing more innovative tools and equipment for FTS while also enhancing our operations.

Originally from Las Vegas, Anton appreciates Missouri’s vibrant culture and enjoys traveling with friends and family to discover new places, the best lake spots, and some good bowling alleys. He relocated to Missouri in 2018, finding his happy place near the Lake of the Ozarks. Anton and his wife, Sara, like crafting unique homemade meals, spending time at the lake, and exploring on his electric skateboard or their bikes. His skill and creativity make him an integral part of the FTS team.

Chase Kurtz

Marketing Director

Missouri State University – Bachelor of Science in Marketing & Management

Chase Kurtz is the Marketing Director at FTS, leading the way in sharing our brand and values with the world. He effectively communicates who we are and what we do, embodying our culture of hard work, honesty, and the “under promise, over perform” attitude. Chase ensures our message is delivered clearly, digitally, and physically highlighting our capabilities, products, and services while building relationships with new customers.

Chase enjoys being with his wife and three cats in his free time, tinkering in his wood crafting shop, and other projects. His passion for business was inspired by his father’s footsteps and by his desire to always make things happen. Chase values his close-knit family and has a lifelong love of soccer, outdoor activities, hiking, kayaking, and being near water. His intricate skills and enthusiasm make him an essential part of the FTS team.

Paula Thomson

Bookkeeping

Paula Thomson brings over two decades of experience to the FTS team, specializing in all aspects of financial management and reporting. She plays a vital role in developing and maintaining accounting principles, practices, and procedures to ensure accurate and timely financial statements. As a forward thinker, Paula is always optimizing processes for the future and has a goal to learn something new every day. In her spare time, she enjoys spending time with her husband and sightseeing area attractions plus historical sites.

At FTS, Paula is in charge of bookkeeping, payroll, and accounts payable oversight, ensuring that the financial operations run smoothly and efficiently. She is also responsible for preparing financial reports, managing accounting oversight, and coordinating year-end audit preparations. Paula’s ability to handle tight deadlines and manage multiple projects with precision makes her an invaluable asset to our team. Her commitment to accuracy and clear communication ensures that FTS remains financially robust and ready for future growth.

Jeff Lexvold

Lead Applications Engineer

Jeff Lexvold brings over two decades of engineering expertise to Fiberglass Tank Solutions (FTS). As our Lead Applications Engineer, Jeff plays a key role in applications engineering, technical support, and ensuring seamless project execution. With extensive experience in civil engineering, Jeff works closely with customers to understand their needs and deliver innovative solutions. His responsibilities include writing product specifications, overseeing technical sales materials, and managing company certifications and industry compliance.

Before joining FTS, Jeff gained valuable experience managing engineering teams and coordinating across departments in manufacturing, sales, and field service. His passion for problem-solving and optimizing processes aligns perfectly with FTS’s mission.

Originally from Minnesota, Jeff enjoys spending time with his wife Nicole, family, and their cat. Outside of work, Jeff enjoys spending time with friends & family, kayaking, e-biking, exploring the outdoors, and working on projects that reflect his dedication to precision and craftsmanship.

Amy Van de Ven

Purchasing Agent

The Fiberglass Tank Solutions Motto “Under-Promise & Over-Perform”

It is unwise to pay too much, but it is worse to pay too little. When you pay too much, you lose a little money… that’s all. But when you pay too little, you sometimes lose everything, because what you designed and purchased was incapable of doing what it was expected to do.

The Common Law of Business Balance prohibits paying very little and getting a lot… it can’t be done. If you deal with the lowest bidder or the cheapest product, it is well-advised to add contingency costs due to the risk you run. If you do that, you will have enough to pay for something better!