The Best Fiberglass Solution for Wet Well and Rehabilitation Insert Projects

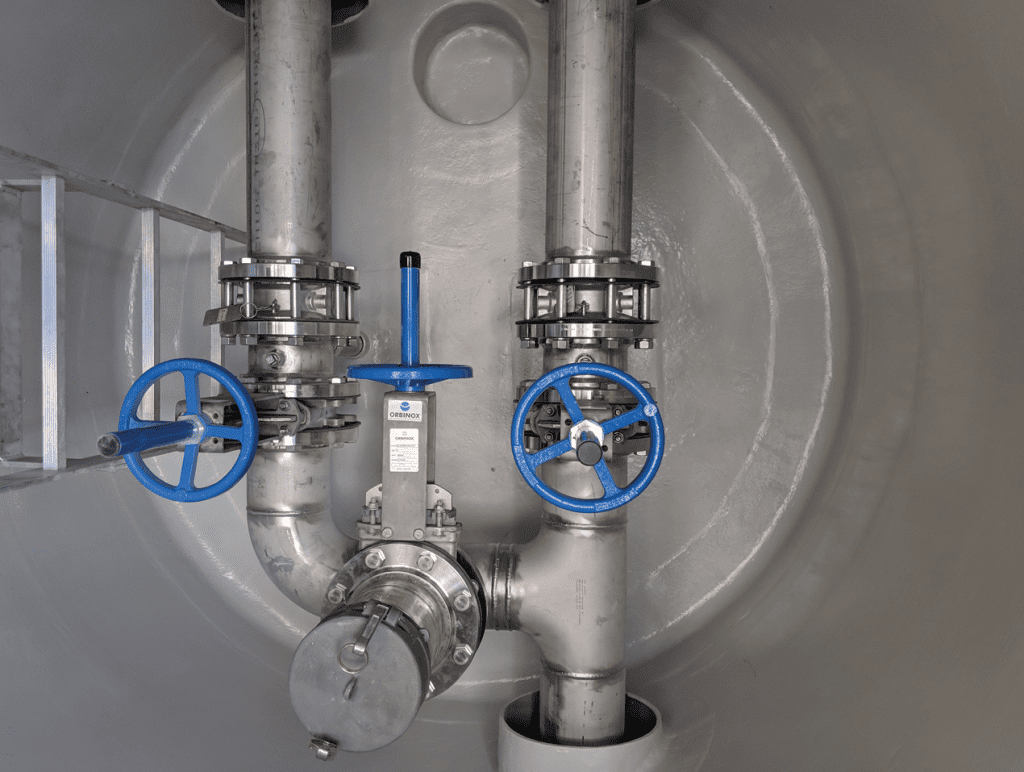

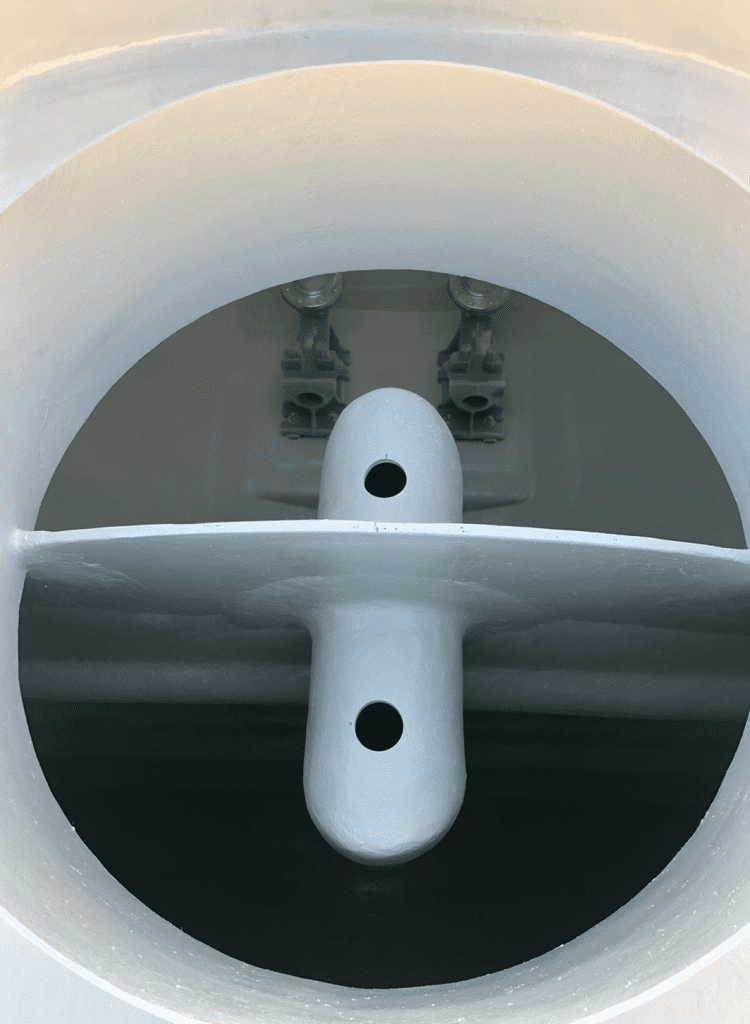

Fiberglass Tank Solutions builds lift stations for the municipal, industrial, and commercial markets. We build and prepackage fiberglass wet wells with piping, pump accessories, rails, and covers, making a turnkey system.

The majority of lift stations in service today are concrete. The corrosive presence of H2S in wastewater is highly corrosive to concrete, reducing the lifespan of the system and creating maintenance problems.

Unlike coatings that need to be re-applied over time, fiberglass wet wells are a standalone, structural solution. Fiberglass resins are highly resistant to corrosion in industrial or municipal wastewater applications. Pre-packaging provides installation and assembly of all internal components in a quality-controlled manufacturing facility, instead of in the field, where deep confined space entry can create hazardous work conditions.

Fiberglass Tank Solutions can also provide structural, mechanical, and buoyancy calculations for our wet wells.

- Buoyancy calculations estimate a condition where the wet well is fully flooded to finish grade, with the wet well empty

- Mechanical calculations could include a pump motor experiencing a locked rotor condition

- Laminate tear-out strength for pumps up to 200 HP are examples of our abilities

- Structural calculations used for our wet wells are designed to offset side wall buckling and bottom deflection

- Wet well bottoms are designed with < ⅜” deflection, without the use of concrete in the wet well base

All of our competitors require additional concrete to stiffen their bases, adding cost and contractor risk to the function of the wet well.

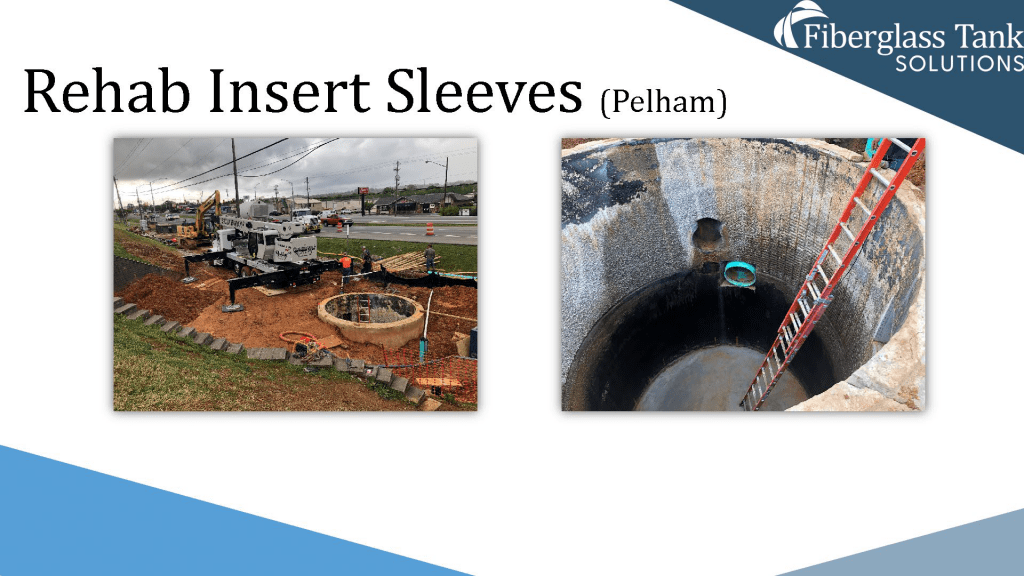

Rehabilitation

Your lift station or manhole just might have some life left in them – We can help with that.

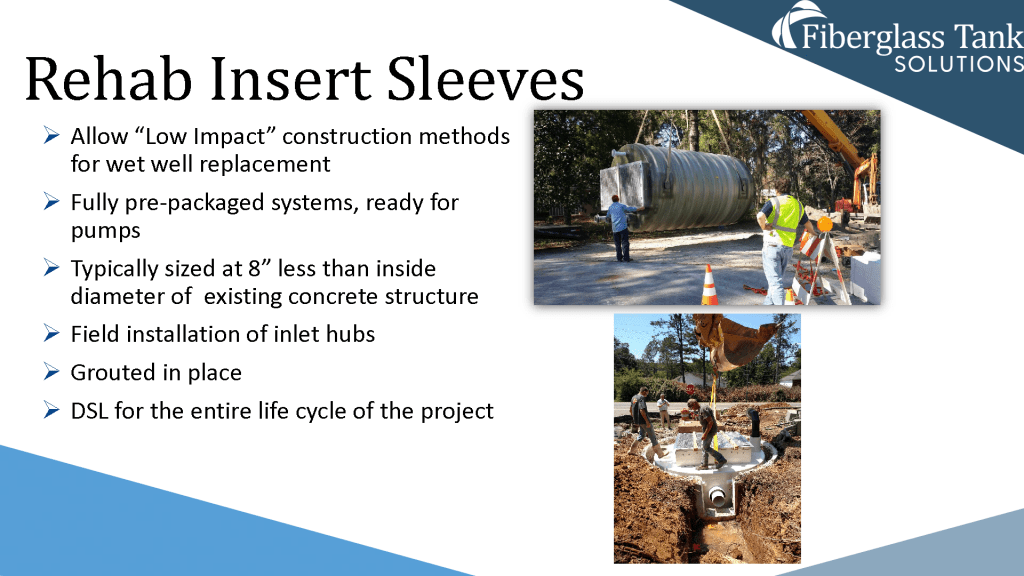

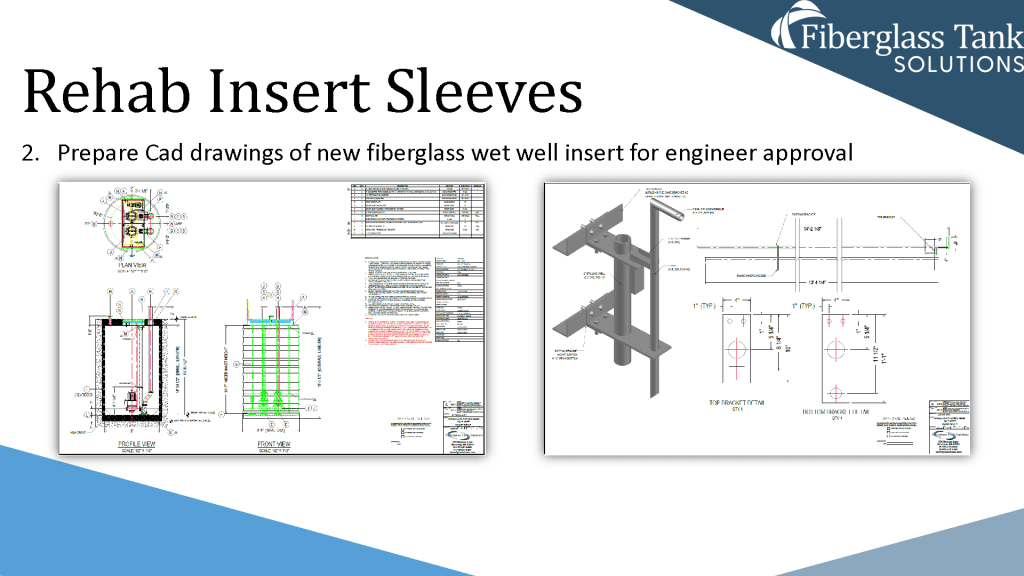

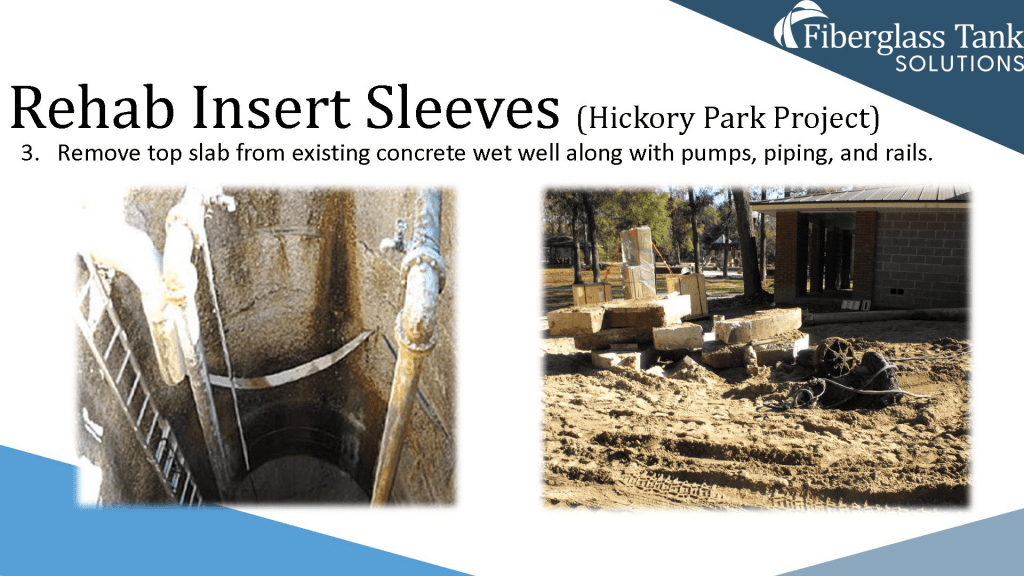

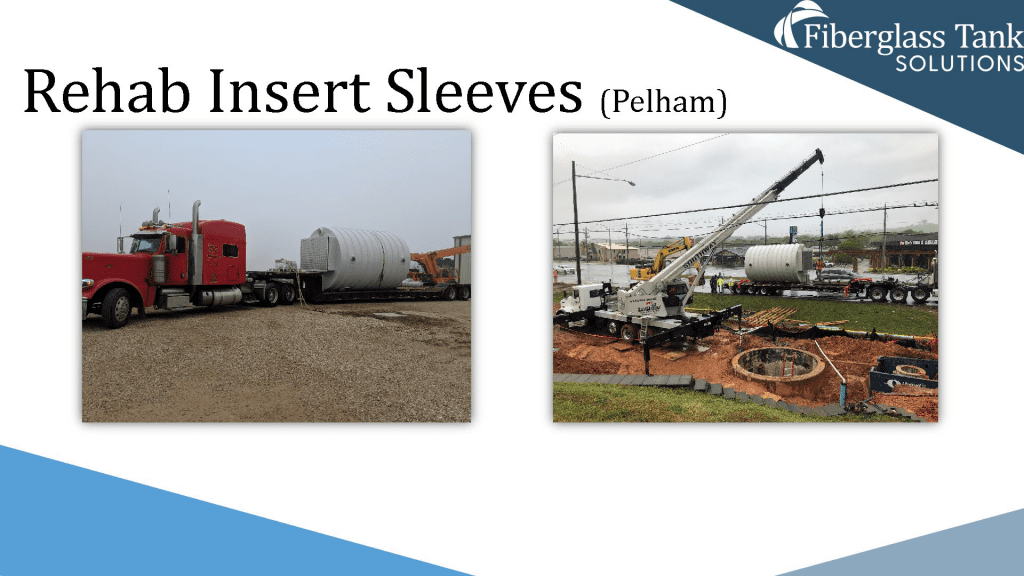

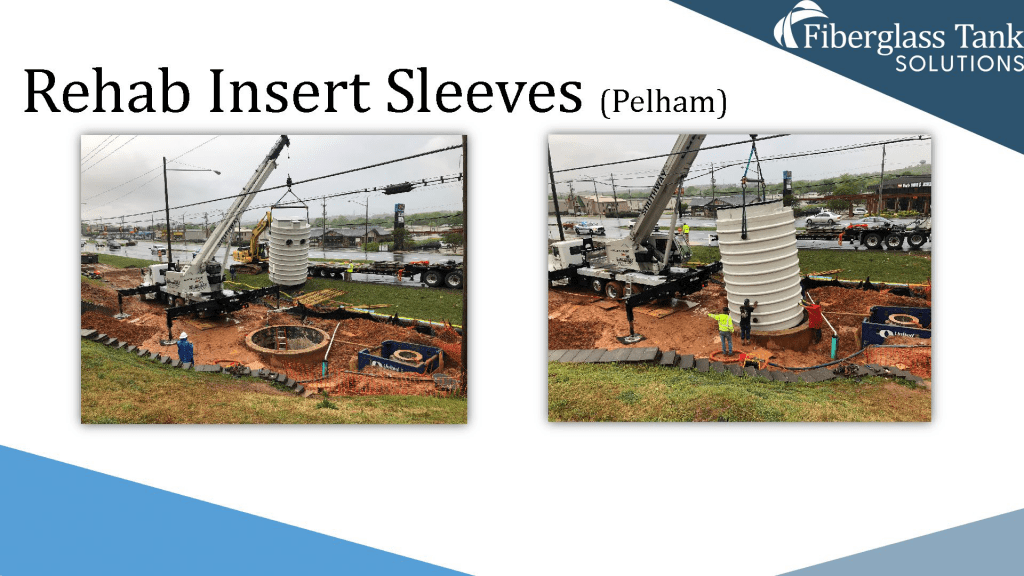

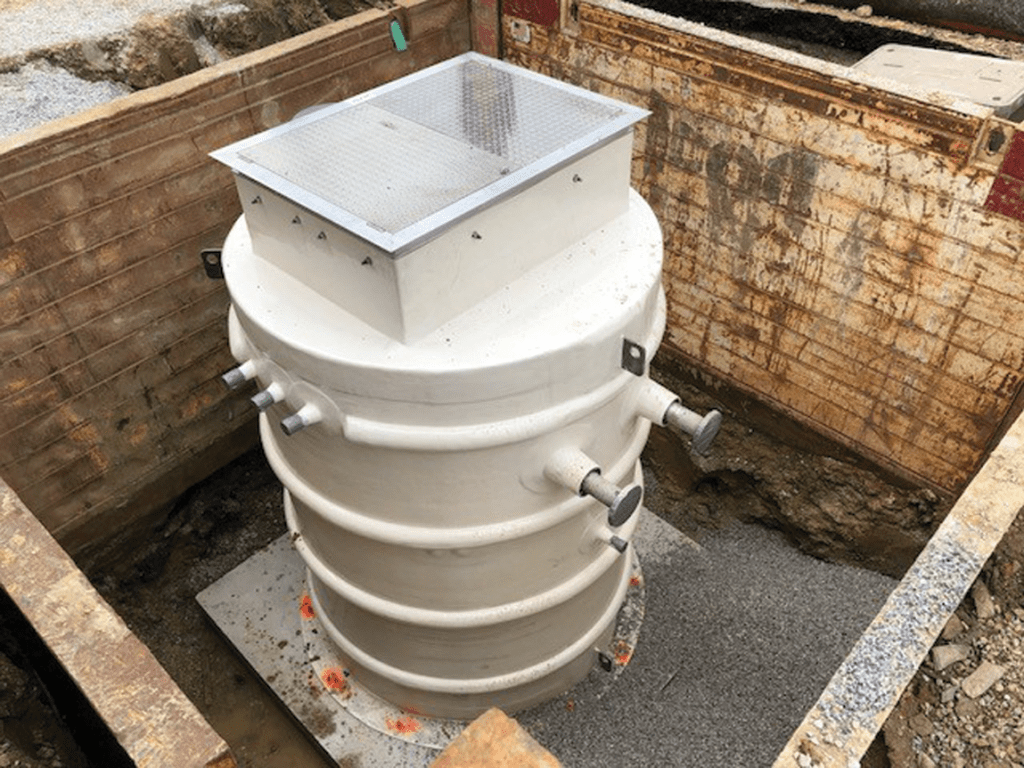

Fiberglass Tank Solutions provides rehabilitation inserts, which are custom-built and prepackaged to fit inside worn out concrete lift stations. These inserts eliminate replacement costs and offer a much faster turnaround compared to installing new replacement stations. You’ll be amazed by how things go much faster when large-scale excavation and bypass pumping are not involved.

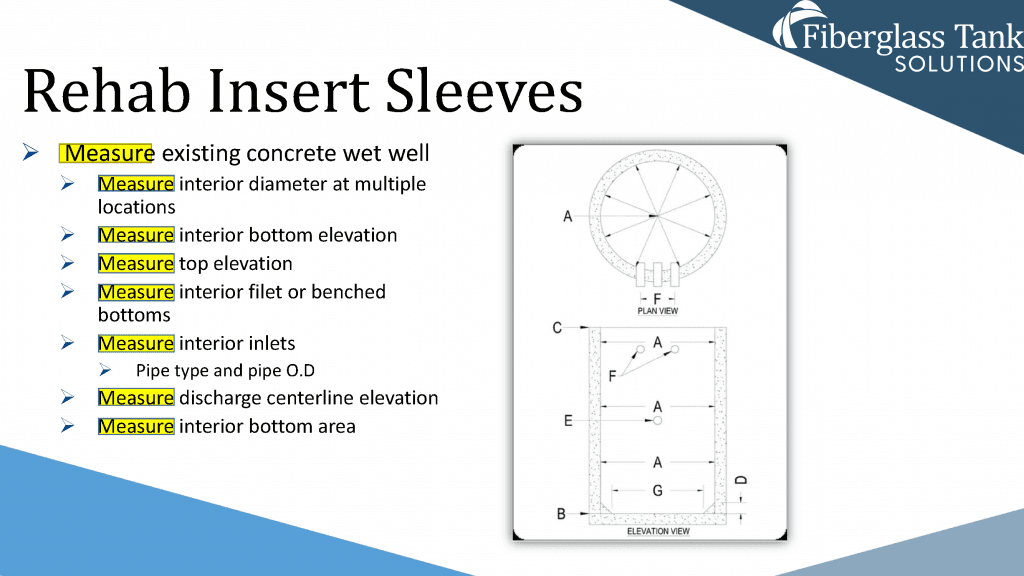

Rehabilitation Inserts for Existing Concrete Wet Wells

Rehabilitation inserts are an ideal method for existing concrete wet wells that are structurally deficient and at the end of their life cycle. Hydrogen Sulfide can be extremely corrosive to concrete wet wells and can cause structural degradation in a very short time. As sewer collection systems eliminate infiltration and inflow, these gas concentrations can increase. Entering force mains can also be a strong source of H2S corrosion.

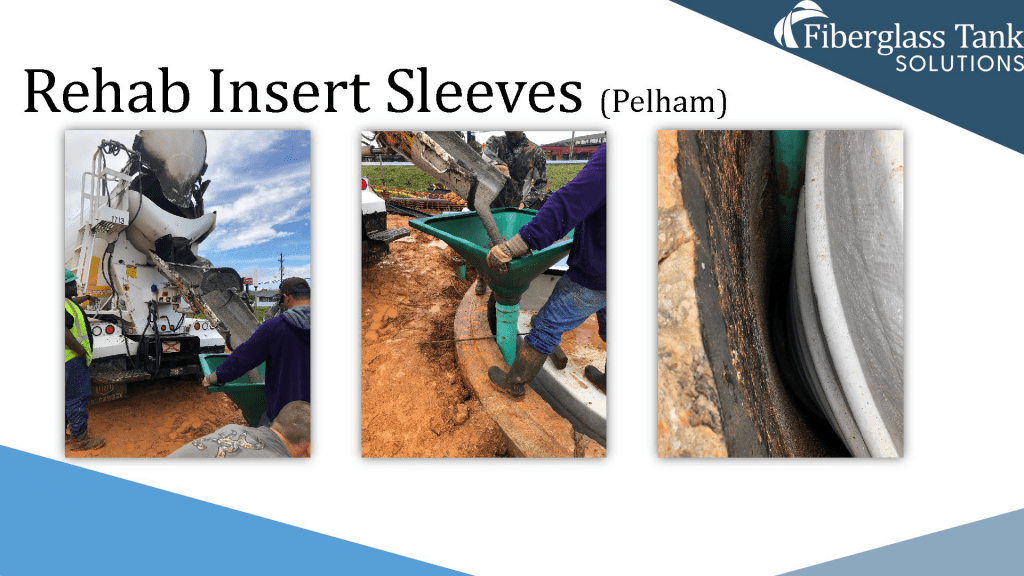

Fiberglass wet well rehabilitation inserts are built to fit the inside diameter of the existing concrete wet well. The existing concrete wet well simply provides a shored structure to accept the new fiberglass insert. These Fiber Reinforced Plastic (FRP) inserts have all the structural features of a conventional fiberglass wet well and come fully kitted up with pump base elbows, rails, and accessories for a turn-key station. The installation of a rehabilitation insert takes days instead of weeks, as compared to conventional construction techniques, eliminating costs, and providing a long-term solution.