We Are The Underground Storage Tank Experts

There is a reason why the word “Solutions” is in our name. Every Underground Fiberglass Storage Tank that we build has its own set of unique conditions, features, and customization to meet the tanks intended application. Fiberglass Tank Solutions builds CUSTOM undergrounds tanks with market specific accessories, piping systems, optional equipment kit-up, and anti-flotation systems. Our tank designs are professionally engineered (PE) to industry standards and include full Finite Element Analysis as a blueprint for manufacturing. We provide buoyancy calculations and can also provide P.E. Stamped designs for over 40 States.

From your initial contact with our knowledgeable and responsive sales team, to manufacturing by our experienced workforce, through the final tank delivery coordination, we promise that as our customer, you will get the personal attention needed to provide a successful underground water storage tank installation.

Powerful Underground Water Storage Solutions

Benefits of Underground Fiberglass Storage Tanks

In many cases, underground fiberglass storage tanks can provide significant advantages over above ground tanks. Here are a few benefits that may be relevant to your specific situation:

- Underground tanks are often less expensive than above ground tanks, due to the fact that they require less land and fewer support structures.

- They are also more aesthetically pleasing, since they are hidden from view.

- Underground fiberglass storage tanks are highly durable and can withstand even the most severe weather conditions.

- They are also very easy to maintain and inspect, thanks to their access hatches.

- Finally, underground tanks can help to protect your stored water from contamination, since they are less likely to be breached by vandals or animals.

If you need to store a large quantity of water, an underground water tank may be the perfect solution for your industrial or business application. There are many benefits to using an underground water tank, including the fact that they are often less expensive than above ground tanks, they are more aesthetically pleasing, and they can help to protect your stored water from contamination. Give us a call today to learn more about our underground water tanks and how they can benefit you!

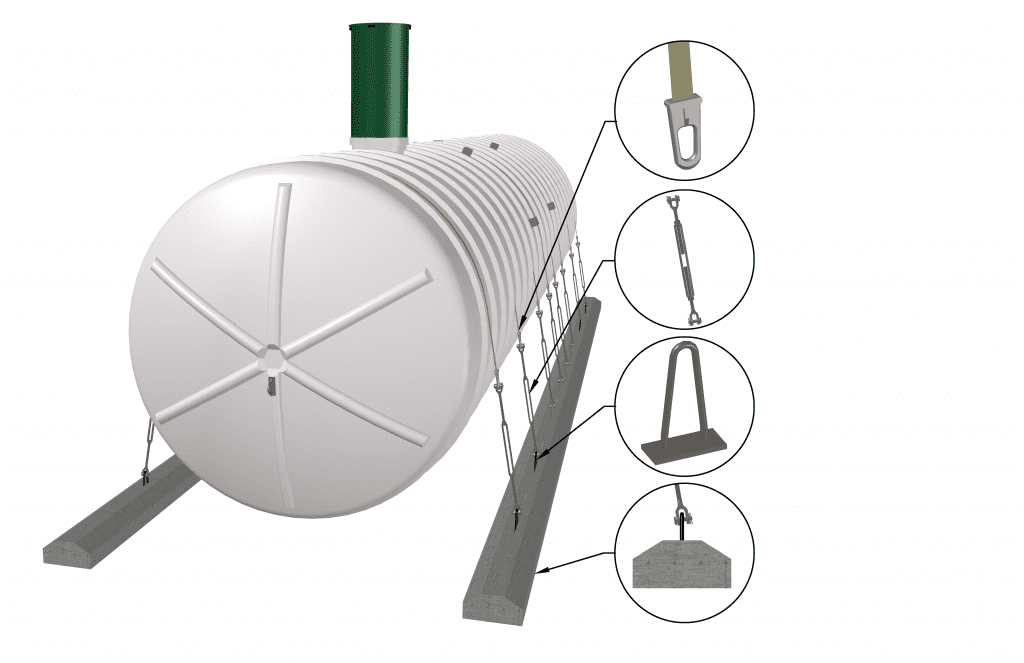

Engineered Anti-flotation Systems for Underground Fiberglass Storage Tanks

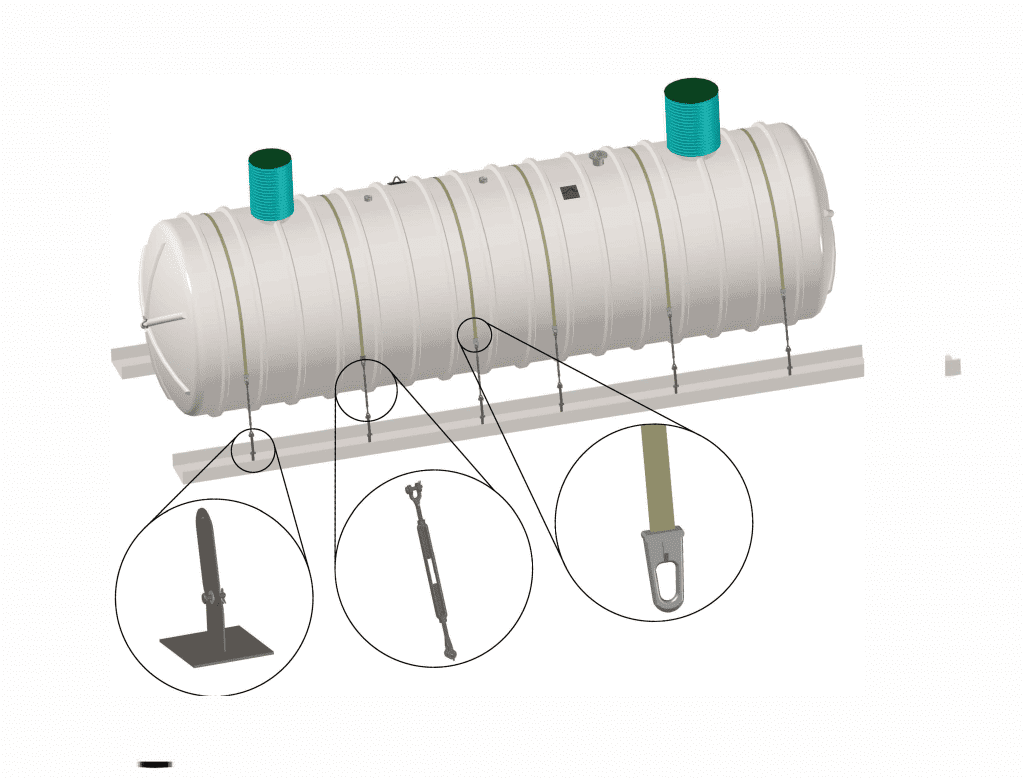

Tanks with inadequate cover and high groundwater conditions can easily become buoyant. Anchoring systems and proper soil back-fill are common ways to offset flotation of underground storage tanks. Fiberglass Tank Solutions offers three options when it comes to anchoring systems. All three of these anti-flotation systems can be provided with structural and buoyancy calculation with P.E. stamps for over 40 States.

Concrete Deadman System

As an industry standard, Fiberglass Tank Solutions provides a conventional concrete Deadman system. Concrete has been used for tank anti-flotation systems for over 50 years and is a time proven system. Our concrete Deadman systems are engineered for structural strength, have adjustable hook points, designed and manufactured in house, and come in a tapered design to easily ship with most tanks up to 10’ in diameter. Concrete Deadman systems come complete with everything you need in one place: anchor points, turnbuckles, and straps to provide a fully integrated anchoring system.

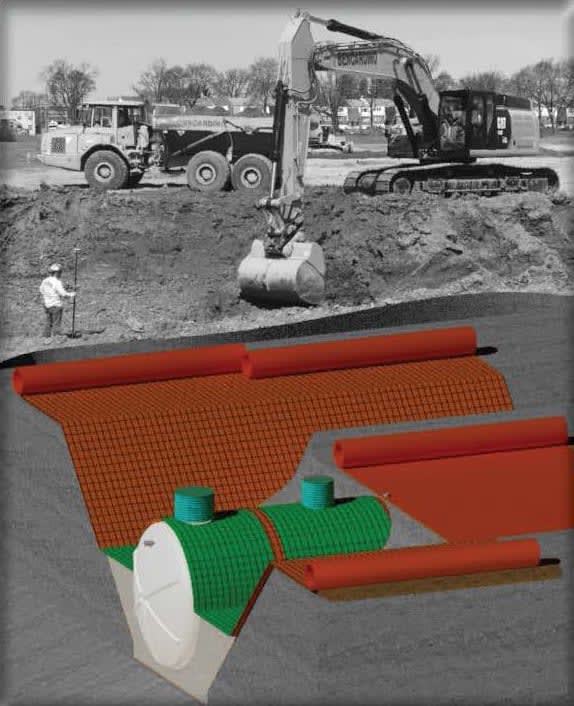

TankAnchor™

TankAnchor™ is a Geo-composite comprised of a coated high strength polyester geogrid bonded to a polyester non-woven geotextile, designed for superior anti-buoyancy resistance for installation of underground storage tanks.

As compared to conventional concrete Deadman systems, TankAnchor™ provides an anti-flotation system with higher safety factors, and shallower bury depths for both single and double tank installations. This anti-flotation method does not require special tools, is manufactured from corrosive resistant material, and is less costly than conventional methods.

· Allow for shallower bury depths

· Less costly

· No special tools needed

· Fits Single or Double tank installations

· P. E. stamped calculations

Fiberglass Deadman System (FDS)

Fiberglass Tank Solutions also provides an internally engineered FDS that is lightweight, easier to handle and ship than concrete, and can usually ride on the same truck, saving freight dollars. This Fiberglass anchoring system installs quickly and uses the soil load over the top of the tank and the soil load above the anchor system to offset buoyancy. The FDS anchoring system comes with flexible anchoring points and utilize protruded FRP straps, galvanized turnbuckles, and anchor points to complete the anchoring system.