At Fiberglass Tank Solutions we manufacture customized underground storage tanks to meet your specific application needs. Each tank we manufacture is engineered to industry standards with precise customizations, including market-specific accessories, piping systems, and anti-flotation features.

Looking for a tailored underground tank solution? Contact us today to get started.

There is a reason why the word “Solutions” is in our name. Every underground storage tank we build is customized to meet the tank’s intended application. Our tanks are professionally engineered (P.E.) to industry standards and include complete Finite Element Analysis as a blueprint for manufacturing. We also provide buoyancy calculations and offer P.E. Stamped designs for over 40 States.

When you work with Fiberglass Tank Solutions, you will get the personal attention needed to provide a successful underground water storage tank installation. Starting from your initial contact with our knowledgeable and responsive sales team to manufacturing by our experienced workforce and final tank delivery coordination.

Reach out to our expert team today to learn how our custom solutions can benefit your project!

There can be a wide range of corrosive elements in products that need to be collected and stored in underground tanks. Water can be corrosive, especially to steel and concrete, and when high or low pH, chemicals, elevated temperatures, or by products are also present, a highly corrosive environment is created. Fiberglass tanks are built with thermostat resins that withstand corrosive environments. By resisting corrosive elements and environments these underground storage tanks exceed the life span of alternatives like steel or concrete.

Fiberglass tanks are stronger than steel or concrete. Our fiberglass storage tanks are built to withstand upthrust from groundwater, offset sidewall buckling from soil loads, and withstand H-20 traffic loads. Fiberglass storage tanks are also inherently flexible and utilize geometry and sandwich laminate construction techniques proven for underground applications. These designs are mathematically calculated and manufactured with quantitative industry safety factors. As an example, our standard tanks are designed for 7’ of bury, fully flooded to grade, in an empty condition. We also builds underground storage tanks for deep bury applications, exceeding 7’ of cover.

Unlike concrete, fiberglass is 100% water-tight and testable. For applications in wastewater, potable drinking water, and fire suppression, this is a mandatory requirement. Our Underground Storage Tanks can be built with pressure testable man-ways or they can be hydro-statically tested in the field to provide proof of function. We also build custom double-wall tanks suitable for a variety of applications and stringent regulatory requirements.

Contact us today to learn more about our underground fiberglass storage tanks and how they can benefit you!

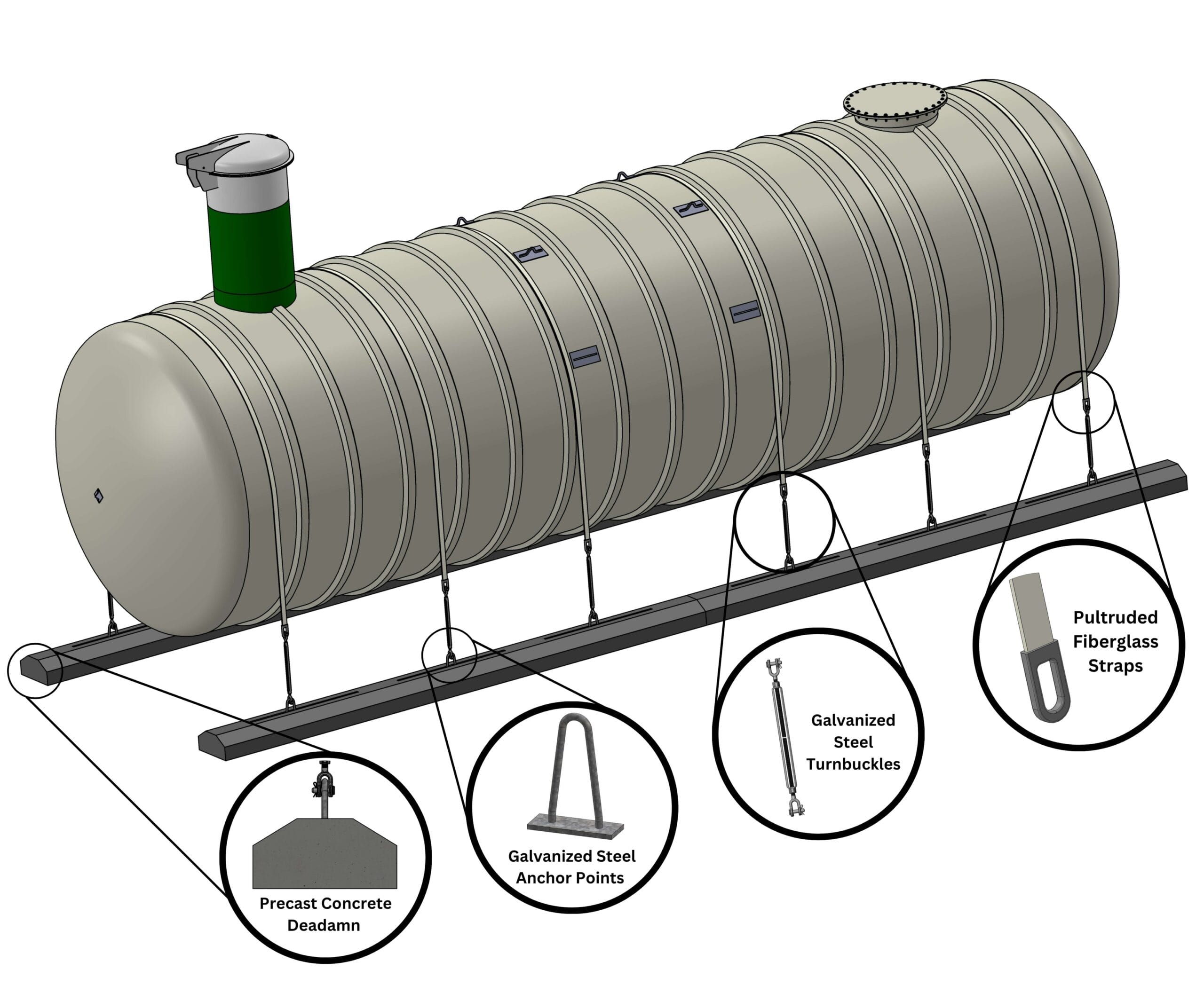

Tanks with inadequate cover and high groundwater conditions can easily become buoyant. Anchoring systems and proper soil backfill are common ways to offset the flotation of underground storage tanks. Fiberglass Tank Solutions offers various options when it comes to anchoring systems, all of which can be provided with structural and buoyancy calculations with P.E. certification for over 40 States.

As an industry standard, Fiberglass Tank Solutions provides a conventional concrete Deadman system. Concrete has been used for tank anti-flotation systems for over 50 years and is a time-proven solution. Our concrete Deadman systems are engineered for structural strength, have adjustable hook points, and are designed and manufactured in-house. They are also fabricated in a tapered design to easily ship with most tanks up to 10 feet in diameter.

Fiberglass Tank Solutions also provides an engineered Fiberglass Deadman System (FDS) that is lightweight, easy to handle, and can be shipped with your fiberglass tank, saving on transport costs. The fiberglass Deadman anchoring system comes with flexible anchoring points and utilizes protruded fiber-reinforced plastic straps, galvanized turnbuckles, and anchor points to secure the anchoring system for life. It installs quickly and uses the soil load above the tank and the anchor system to offset buoyancy.

1. Choose and quote form below

2. Download, Fill and Save Quote.

3. Upload quote to our Quote Upload Form.

Feel free to contact us for any general questions and inquiries here!