Fiberglass Petroleum Storage Tanks

Fuel, Biofuel, and Gasoline Storage Solutions Designed to Sustain Our Future

Fiberglass Tank Solutions (FTS) is a family-owned manufacturer of underground fiberglass storage tanks, based in Central Missouri. We specialize in high-performance tanks for the safe storage of petroleum fuels, biofuels, and other flammable liquids—serving markets including fuel distribution, convenience stores, commercial fueling, and industrial applications.

Our manufacturing process uses automated helical and hoop winding technologies to ensure consistent strength and durability.

All FTS tanks are built to comply with the most current and rigorous industry standard:

ANSI/CAN/UL/ULC 1316:2018 – Fibre Reinforced Underground Tanks for Flammable and Combustible Liquids,

commonly known as UL 1316.

Petroleum Storage Tanks Markets & Applications

Markets

- Retail Fuel Storage Tanks

- Commercial Fuel Storage Tanks

- Oil and Gas Terminals

- Bulk Fuel Storage Facilities

Applications

- Fuel Storage Tanks

- Diesel Exhaust Fluid (DEF) Tanks

- Oil Water Separator (OWS) Tanks

- Pipeline Sump Tanks

What Are UL 1316 Listed Tanks?

For fuel storage installations in the U.S. and Canada, Fiberglass Tank Solutions (FTS) manufactures UL 1316-listed underground fiberglass storage tanks, meeting the most current safety and performance standard:

ANSI/CAN/UL/ULC 1316:2018 – Fibre Reinforced Underground Tanks for Flammable and Combustible Liquids.

Our double-wall tanks are engineered to be 100% watertight and are rigorously designed, manufactured, and tested to meet or exceed the requirements of UL 1316. All tank configurations, accessories, and fittings also comply with UL 1316, applicable NFPA codes, and PEI Recommended Practices for fuel storage.

100% Water Tight

Corrosion Resistant

Lighter Weight

Longer Life Cycle

Why UL 1316 Matters

UL 1316 is more than just a label – it represents a critical benchmark for the safety and performance of underground storage tanks & it ensures:

- Robust structural integrity for long-term reliability.

- Guaranteed long-term compatibility with various fuels and biofuels.

- Effective leak detection sensitivity to protect the environment.

- Superior corrosion resistance for extended tank lifespan.

FTS undergoes regular, unannounced UL audits to ensure continuous compliance. These inspections cover our materials, manufacturing processes, and finished tanks, verifying adherence to our UL file (UL File MH67870). This includes thorough reviews of raw materials and previously shipped tanks, guaranteeing consistent quality and adherence to UL 1316 specifications.

Meeting UL 1316—and Going Beyond

While FTS tanks are proudly UL 1316-listed, our engineering goes beyond these standards. Our tanks feature a 5:1 safety factor against general buckling and are built to withstand challenging conditions, including:

- 7 feet of backfill (standard soil load; deeper burial options available)

- Fully flooded excavations (maximum external water pressure)

- Empty tank conditions (no internal offsetting pressure)

Ideal for convenience stores, commercial fueling stations, and fleet operations, FTS tanks are rigorously tested and proven to perform under extreme conditions, ensuring reliable fuel storage and ready to ship nationwide.

Proven Fiberglass Tank Design: Evolved for Modern Demands

FTS is not the first company to make fiberglass underground storage tanks in the fuel market. As an industry, with over 50 years of fiberglass underground storage tank (UST) evolution behind it, the FTS tank design represents the next generation of performance, durability, and compliance. Early fiberglass USTs were limited by the materials, design tools, and manufacturing technology of their time. FTS builds on those foundations—refining what works and innovating where it counts.

Our design philosophy is rooted in the strategic use of modern automated tooling, high performance resins, and helical/hoop wound fiberglass reinforcements. By separating the tank’s structural and corrosion-resistance functions, we optimize performance in both areas. Certain zones are dedicated to resisting corrosion with ethanol-based fuels, while others are engineered for maximum strength under in-service jobsites burial and hydrostatic loads.

SPACERGLASS™ - 3D Woven Core Reinforcement Technology

- 3D woven E-Glass fabric

- Automatically forms rigid & lightweight sandwich structures when laminated.

- Only core material where deck layers and core are one integral piece

- Delivering exceptional strength-to-weight ratios with versatile design applications.

How we manufacture our tanks - multi-layer composite Construction

Each FTS tank is built using a carefully engineered multi-layered laminate sequence that reflects decades of experience:

- Corrosion-Resistant Barrier = Resin-rich primary barrier of corrosion defense. The internal structural layers.

- Chop = Chopped fiberglass bonds the liner and structural layers together, enhancing durability.

- 3D Spacer Glass Interstitial = Creates the communication and structural tie between primary and secondary.

- Helical & Hoop Winding = True backbone of the structural components in the entire system.

- Uni Directional = Additional support for winding strength in a specific area.

- Monolithic Structural Jacket = Trapezoidal ribs, premium resins, and monolithic jacket for external strength and corrosion.

The Result? A structurally advanced, corrosion-resistant tank engineered to meet today’s stringent UL 1316 requirements and backed by a legacy of real-world performance.

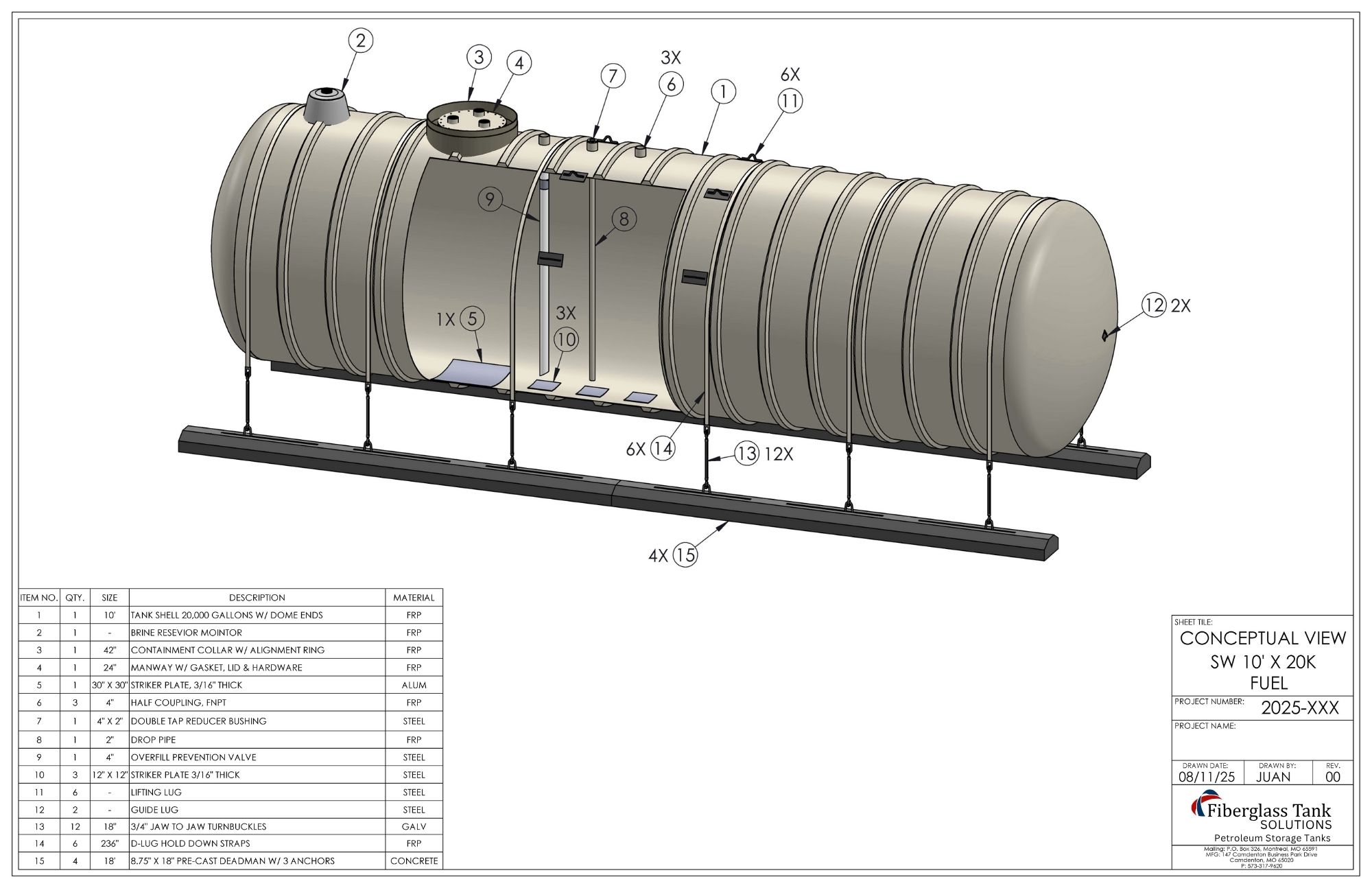

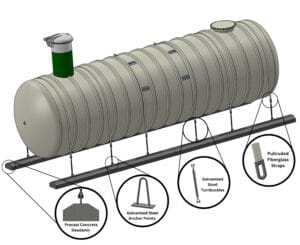

Engineered Anti-Flotation Systems for Fiberglass Underground Storage Tanks

Anchoring systems and proper soil backfill are common ways to offset the flotation of underground storage tanks. Fiberglass Tank Solutions offers various options when it comes to anchoring systems, all of which can be provided with structural and buoyancy calculations.

Concrete Deadman System

- Industry-standard concrete Deadman system engineered to prevent tank flotation.

- Adjustable hook points and tapered construction for easy shipping with tanks up to 10 feet in diameter.

- Built on 50+ years of proven concrete anchoring technology for reliable structural strength.

- Designed and manufactured in-house for quality control.

Fiberglass Deadman System (FDS)

- Lightweight Fiberglass Deadman System engineered anchoring system that’s easy to handle and ships with your tank on step deck to reduce transport costs.

- Flexible anchoring points with fiber-reinforced plastic straps, galvanized turnbuckles, and secure anchor points built to last.

- Quick installation using soil load above the tank to offset buoyancy.

- Durable, lifetime anchoring solution designed for reliable performance.

Lifting Slings & Our Move to Safety

Safety Benefits:

- Ground-Level Hookups

- No Ladders

- No Men on Tank

- One Man Process

- Labor and Time Savings

Pre-fitted polyester web slings rated for tank weight allow direct hook attachment without a spreader bar, enabling lift-off in shipped position and rotation if needed before burial with the tank.

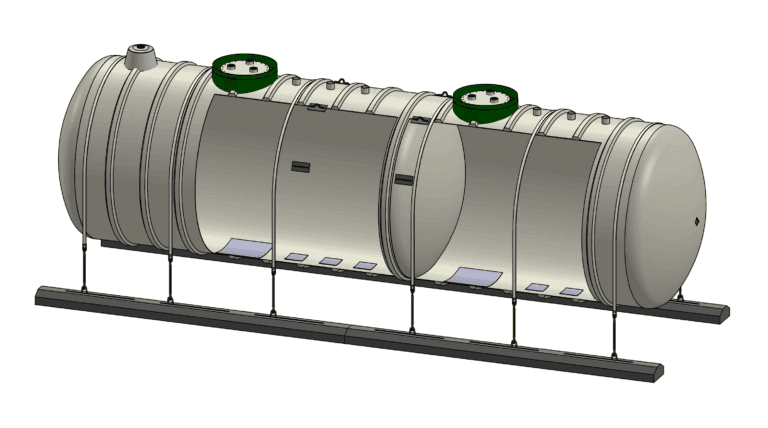

Line Drawings

View some line drawings for typical applications that we design and manufacture to comply with industry and client standards.

Explore some of our standard tank options below or contact us today to learn more about our custom options.